Synthetic biology is transforming 3D food printing by allowing you to create personalized, sustainable meals through engineered microorganisms and advanced bioinks. Microbes can produce flavors, colors, and nutrients within the printed structures, enabling custom nutrition and aesthetic design. Bioprinting technology offers precise control over texture and appearance, supporting innovative and eco-friendly food solutions. To explore how these cutting-edge techniques are shaping the future of food, keep exploring this exciting field.

Key Takeaways

- Synthetic biology enables engineering microorganisms to produce customized ingredients like flavors, colors, and nutrients for 3D printed foods.

- Genetically modified cells can be embedded in bioinks to create functional, living food structures capable of growth and repair.

- Microbial biosynthesis supports sustainable, scalable production of bioactive compounds used in personalized 3D food printing.

- Synthetic biology allows precise control over nutrient distribution and bioavailability within complex, layered 3D printed foods.

- Ethical and regulatory considerations are vital for safe integration of genetically engineered organisms in 3D food printing.

Understanding the Basics of 3D-Printed Food

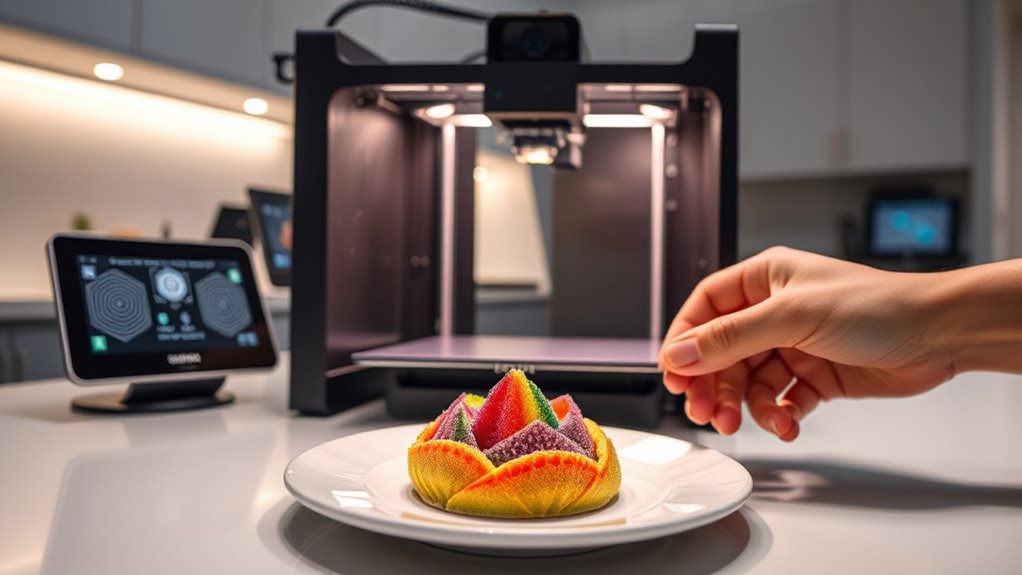

Have you ever wondered how 3D-printed food works? It’s all about food printing, a process that uses additive manufacturing to build edible items layer by layer.

You start with a digital design created using CAD software, which lets you customize shapes, flavors, and nutrients. The printer extrudes malleable ingredients like chocolate, cheese, or plant-based proteins onto a surface, often heated to make the food more workable without cooking it.

This allows for precise control over texture and appearance. Food printing technology continues to evolve, offering innovative ways to prepare personalized meals efficiently. The choice of printable ingredients significantly impacts the texture, flavor, and nutritional content of the final product.

In addition, advancements in food safety standards are essential to ensure that printed foods meet health regulations and are safe for consumption. Implementing quality control measures is crucial for maintaining safety and consistency in food printing. Common foods used in food printing include pasta, mashed potatoes, and cheese. Incorporating nutritional content into the design process can help optimize health benefits in the final product.

The technology is gaining attention for its potential in healthcare, space missions, and sustainable food production, offering innovative ways to prepare personalized meals efficiently.

The Role of Synthetic Biology in Food Manufacturing

Synthetic biology plays a pivotal role in revolutionizing food manufacturing by enabling the design and modification of biological systems to produce essential ingredients more efficiently. It allows you to engineer microorganisms like bacteria, yeast, and algae to biosynthesize proteins, flavors, and nutrients for 3D printed foods. Using genetic techniques, you can develop bioinks containing plant or microbial cells that grow, self-repair, or produce metabolites within printed structures. This approach reduces reliance on traditional farming and animal agriculture, promoting sustainability and scalability. Additionally, research-supported bioengineering enables the development of novel food sources that can be tailored to specific nutritional needs. Historical use of chia seeds illustrates how seed-based ingredients have long contributed to nutritious and sustainable diets, inspiring modern bioengineering efforts. Furthermore, advances in biotechnological methods are expanding the potential for creating personalized and functional foods through 3D printing. Additionally, integrating farmhouse kitchen textiles and accessories concepts can enhance the presentation and appeal of 3D printed foods in a rustic or homely setting. The application of state-specific incentives can also accelerate adoption and innovation in synthetic food production.

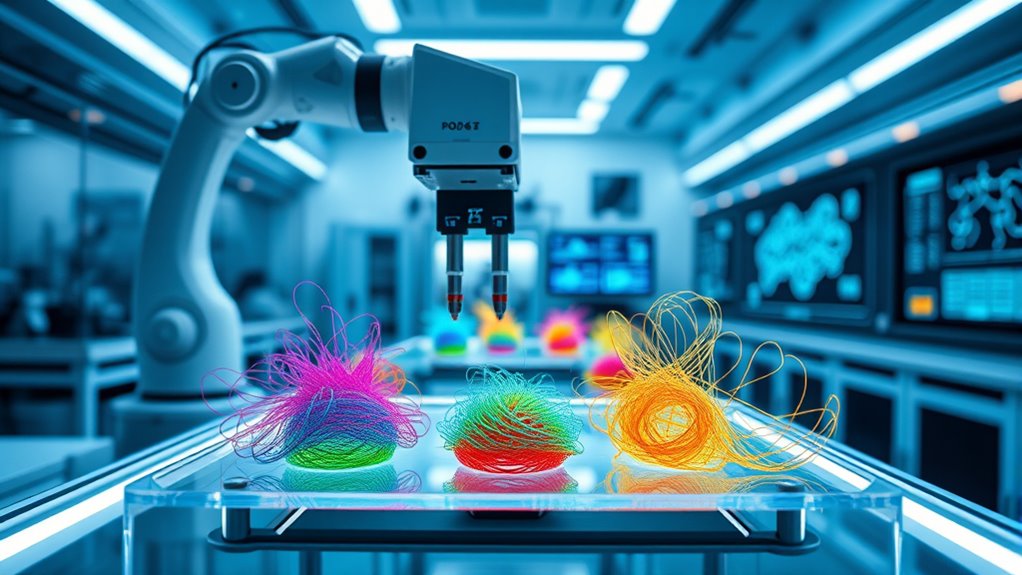

How Bioprinting Technologies Enable Food Customization

Bioprinting technologies let you place living cells precisely where you’d like, creating customized food structures. This control enables programmable foods that can grow, repair, or adapt to your needs.

With enhanced nutritional control, you can design meals tailored specifically to your health and taste preferences.

Precision in Cell Placement

Advancements in bioprinting enable precise placement of cells and bioinks, allowing for the creation of customized food structures with specific spatial arrangements. This precision is achieved through additive manufacturing techniques combined with digital design, giving you full control over the positioning of cells within the food matrix. Regular prenatal check-ups are essential for monitoring fetal development, which underscores the importance of precise and careful planning—paralleling how bioprinting requires meticulous accuracy. High-resolution nozzles and computer-controlled algorithms ensure micron-scale accuracy in printing food, making complex, multifunctional structures possible. By controlling cell placement, you can develop foods with tailored nutritional profiles, such as probiotic-rich zones or flavor-enhancing clusters. This technology supports food production that isn’t only personalized but also highly targeted, enabling the development of layered or biologically active foods that meet specific health or sensory needs. Regional legal resources can influence the regulatory landscape for innovative food technologies, ensuring compliance and safety standards are met. Additionally, incorporating durable survival gear can be useful for field testing and emergency situations when deploying new food printing technologies in remote or challenging environments. Advances in biofabrication are also enabling the creation of complex food structures that mimic traditional textures and flavors with greater precision. Legal compliance is crucial for the commercial adoption of bioprinted foods, ensuring they meet all safety and quality standards. Precision in cell placement is a key driver in the future of food innovation.

Programmable Food Structures

Programmable food structures harness bioprinting technology to precisely arrange ingredients and create highly customized edible designs. With programmable food structures, you can control the placement of bioinks containing living cells, such as plant or microbial cells, to craft complex, tailored foods. These structures enable the incorporation of genetically modified cells that produce specific metabolites, pigments, or pharmaceuticals directly within the food. Advanced bioprinting techniques allow for the spatial organization of cells and bioactive compounds, resulting in multifunctional and responsive edible products. Regular maintenance and cleaning of bioprinting equipment are essential to ensure optimal performance and prevent contamination. Ensuring the safety and hygiene of bioprinting processes is crucial for producing high-quality, safe food products. Incorporating automotive cleaning procedures can help maintain bioprinting machinery and uphold strict hygiene standards. This approach supports the development of sustainable foods with targeted textures, flavors, and nutritional profiles. Additionally, implementing proper sterilization techniques is vital for preventing microbial growth and maintaining a sterile environment in bioprinting laboratories. By leveraging programmable food structures, you gain the ability to innovate in food design, making meals more personalized, healthful, and aligned with individual preferences. Additionally, understanding the cleaning procedures for bioprinting machinery helps maintain its longevity and performance.

Enhanced Nutritional Control

By controlling the placement of nutrients, vitamins, and bioactive compounds during the bioprinting process, you can create foods tailored to specific dietary needs. This ability enhances the potential of printed food to meet individual health requirements, offering a wide range of customized options. Regulatory compliance is essential to ensure that these innovative foods meet safety standards and legal requirements. Unlike conventional farming methods, bioprinting allows precise placement of food material, ensuring ideal nutrient distribution and bioavailability. This technology enables the production of sustainable food that reduces waste and resource use. Using computer-aided design, you can craft the desired shape and nutrient profile, making personalized meals feasible. Companies like Revo Foods demonstrate how this advanced printing process can deliver nutritious, life as well as eco-friendly printed food. Such innovations in Food Science are transforming how we approach food customization and health, especially with the integration of food safety standards and quality controls, which are critical for consumer trust and safety. Additionally, maintaining proper asset division procedures in the development and commercialization of bioprinted foods can help manage intellectual property rights and investments effectively. Furthermore, ongoing research into interactive STEM toys can inspire the next generation of innovators in bioprinting and food technology.

The Use of Engineered Microorganisms in Food Production

Engineered microorganisms like bacteria, fungi, and algae are transforming food production by serving as biological factories that produce specific ingredients such as pigments, flavors, and nutrients through genetic modification. These microorganisms can be embedded within bioinks and printed in 3D structures, creating living, functional food materials capable of growth and self-repair. With advanced genetic techniques, bacteria can transfer DNA to plant cells, enabling the production of bioactive compounds like betalains and fluorescent proteins within 3D-printed plant tissues. Programmed microorganisms can also produce targeted metabolites, including natural colorants or pharmaceuticals, directly inside the printed food. This integration of engineered microorganisms in 3D food printing offers a pathway to sustainable, customizable, and biologically active foods with complex functionalities. AI Bifurcation insights highlight how such innovations may influence future societal and economic structures in food systems.

Developing Edible Bioinks With Living Cells

Developing edible bioinks with living cells involves integrating genetically modified plant, bacterial, or fungal cells into biocompatible materials to create functional, printable food structures. These bioinks combine living cells with substances like hydrogels, gelatin, and plant-derived compounds, supporting cell survival during printing.

As you print food, the living cells can produce beneficial metabolites, such as pigments or proteins, through genetic engineering after printing. This approach allows for precise spatial control over cell placement, enabling the creation of complex, multifunctional food structures.

With this technology, you can produce personalized nutritional foods, natural colorants, or even plant-based pharmaceuticals directly through food printing. Edible bioinks with living cells push the boundaries of how we design and manufacture food, making it more customizable and biologically active.

Creating Complex Food Structures and Textures

Creating complex food structures and textures with 3D printing allows you to precisely control the shape, layering, and physical properties of your edible designs. By layering edible materials in intricate patterns, you can craft foods with unique visual appeal and mouthfeel.

Techniques like embedding cells within edible matrices enable the development of structured, multifunctional foods with specific physical and biological properties. Advanced bioinks containing genetically modified plant cells can produce localized pigments, flavors, and nutrients within complex shapes.

Manipulating infill patterns and layer deposition methods allows you to tailor textures and mouthfeel, creating sensory experiences beyond traditional cooking. This approach combines biological components with structural design to produce foods with innovative textures, enhanced nutritional profiles, and visually stunning appearances.

Benefits of 3D Printing for Sustainability and Nutrition

3D printing food helps cut waste by allowing precise portioning and ingredient use. It also makes it possible to customize foods with specific nutrients, supporting better health.

Reduces Food Waste

One of the key benefits of 3D food printing is its ability to substantially reduce food waste. By precisely depositing ingredients based on digital recipes, you minimize overproduction and leftovers. This technology allows you to utilize surplus or imperfect ingredients, transforming them into visually appealing and nutritious foods.

Plus, customized portion control helps prevent preparing or consuming more food than necessary. You can also support sustainable sourcing by incorporating alternative proteins and recycled ingredients, lowering your environmental impact. This approach promotes more efficient and resource-conscious food systems overall.

- Uses surplus or imperfect ingredients creatively

- Eliminates excess leftovers and overproduction

- Ensures precise portion sizes to minimize waste

- Supports sustainable sourcing with recycled and alternative ingredients

Enables Nutritional Customization

By using digital recipes to deposit ingredients precisely, 3D food printing not only reduces waste but also opens up new possibilities for tailoring nutrition to individual needs. This technology allows you to embed specific vitamins, minerals, or probiotics into foods, enhancing their nutritional value. You can customize meals for those with special dietary requirements, like the elderly or athletes, ensuring they get the right nutrients. This personalization supports better health outcomes and helps meet unique health goals. Here’s a quick look at what makes this possible:

| Nutritional Customization Benefits | Examples |

|---|---|

| Precise nutrient control | Vitamins, minerals, probiotics |

| Tailored for individual needs | Special diets, health conditions |

| Promotes health and wellness | Optimized nutrient delivery |

Supports Sustainable Food Systems

Using innovative 3D printing technology, you can create food products with precisely controlled ingredient compositions that minimize waste and make better use of resources. This approach helps reduce excess food production and optimizes resource efficiency.

You can also design customizable foods tailored to specific nutritional needs, supporting healthier diets. The technology’s low-temperature processing conserves energy and lowers environmental impact compared to traditional methods.

Additionally, 3D printing allows for incorporating functional ingredients like probiotics or plant-based proteins, promoting sustainable and health-conscious diets. By enabling on-demand, localized food manufacturing, it decreases transportation emissions and strengthens resilient food systems.

- Reduces food waste through precise ingredient control

- Supports energy-efficient, low-impact processing

- Promotes local, on-demand food production

- Incorporates sustainable, functional ingredients

Challenges and Limitations of Synthetic Food Printing

Despite the promising potential of synthetic food printing, several significant challenges hinder its widespread adoption. You’ll find that ingredient variety is limited, restricting the range of foods you can create.

High equipment costs, often over $1,000 to $5,000, make it difficult for many to get started. Maintaining consistent texture, taste, and nutritional content is another hurdle due to current technological limits.

Safety regulations and standards are still evolving, which can delay approval and market entry. Scaling up production for mass markets presents technical and logistical obstacles that need addressing.

These issues collectively slow progress, making it clear that while the technology is promising, substantial work remains before synthetic food printing becomes mainstream.

Future Directions in 3D Bioprinted Foods

Future directions in 3D bioprinted foods aim to create edible products that aren’t only nutritious and customizable but also capable of mimicking natural textures and flavors. You’ll see innovations integrating living cells with advanced bioinks to produce functional, bioactive foods tailored to individual needs.

Researchers are exploring genetically engineered plant and microbial cells that generate specific flavors, colors, or health-promoting compounds within printed structures.

Programmable bioinks are also in development, allowing foods to grow, self-repair, and respond to environmental cues. This progress points toward personalized nutrition, where diets are customized based on your health and preferences.

Additionally, combining synthetic biology with 3D bioprinting offers sustainable solutions, reducing environmental impact and enabling the creation of complex, functional edible materials.

- Personalized, nutritionally tailored foods

- Genetically engineered flavor and color production

- Self-repairing, adaptable edible structures

- Sustainable, eco-friendly food manufacturing

Ethical Considerations and Regulatory Aspects

As innovations in 3D bioprinted foods advance, addressing the ethical and regulatory challenges they pose becomes increasingly important. You need to contemplate food safety, intellectual property rights, and how these new foods might affect traditional culinary cultures.

Regulatory agencies like the FDA and EFSA are still developing guidelines for safety, labeling, and approval processes, so your products might face delays or uncertainties.

When using GMOs or bioengineered cells, transparency and consumer consent are critical, along with understanding long-term health effects.

Ethical debates also include environmental impacts, such as resource use and waste management.

Ensuring equitable access and preventing socioeconomic disparities are essential to fostering responsible innovation and gaining public trust in this emerging field.

Frequently Asked Questions

Is 3D Printing Food Possible?

Yes, 3D printing food is possible today. You can use specialized printers that extrude soft, malleable ingredients like chocolate, mashed potatoes, or plant-based proteins in precise layers.

This technology lets you create customized shapes and textures based on digital designs.

While some challenges remain in scaling up and improving ingredients, the basic process is already working, making 3D printed food a promising and innovative culinary option.

Is PLA Food Safe FDA Approved?

You’re asking if PLA is food safe and FDA approved. While some PLA grades are recognized as safe for food contact and approved for limited uses, not all PLA products are certified for direct food consumption.

You need to check that the specific PLA filament is labeled as FDA-compliant for food contact. Properly manufactured, FDA-approved PLA doesn’t release harmful substances, making it safe for edible applications when verified.

How Is 3D Printing Used in Biology?

Think of 3D printing in biology as building with living Lego bricks. You place tiny layers of cells and materials precisely where needed, creating complex tissues and organs.

This technology lets you develop organ models for testing drugs, studying diseases, or even repairing damaged tissues.

While it’s a breakthrough, challenges like keeping cells alive and ensuring stability over time still need to be addressed, like perfecting a recipe.

Is 3D Printed Meat Safe to Eat?

You’re wondering if 3D-printed meat is safe to eat. The good news is, it’s produced under strict safety protocols, including sterilization and quality checks.

Regulatory agencies like the FDA and USDA are actively developing guidelines to guarantee safety.

When made properly, 3D-printed meat, derived from cultured cells or plant proteins, is free from contaminants and pathogens, making it a safe, nutritious alternative to traditional meat.

Conclusion

So, here you are, marveling at 3D-printed food as a miracle of innovation. Ironically, while it promises sustainability and customization, it’s still rooted in complex biology and regulation. You might think you’re just printing a meal, but behind the scenes, you’re embracing a future where science and ethics collide. Perhaps the real recipe for success is blending technology with responsibility—before printing becomes the only way we nourish ourselves.