Edge-cooling technology keeps your devices cool without fans by using vapor chambers and heat pipes integrated into the device edges. These passive systems transfer heat efficiently through high-conductivity materials like copper and ultra-thin vapor chambers, all within a compact, silent design. They improve reliability, reduce noise, and allow for slimmer gadgets. If you’re curious, exploring how these innovations make device cooling more effective and flexible is worth exploring further.

Key Takeaways

- Edge-cooling integrates vapor chambers and heat pipes into device edges, enabling fanless, passive cooling solutions.

- High thermal conductivity materials like copper and ultra-thin vapor chambers efficiently spread heat without moving parts.

- The technology allows compact, lightweight device designs with silent operation and improved reliability.

- Flexible, ultra-thin vapor chambers conform to curved surfaces, supporting cooling in complex or irregular device geometries.

- Emerging materials and innovative designs enhance heat dissipation, enabling higher performance and longer device lifespan without fans.

Understanding Edge‑Cooling Technology and Its Benefits

Edge-cooling technology passively dissipates heat by integrating vapor chambers and heat pipes directly into a device’s edges, eliminating the need for fans. This approach enhances passive cooling and improves heat dissipation, making thermal management more efficient. Using industry trends insights can help developers stay ahead in thermal design innovation. Additionally, advancements in AI-powered hardware are driving the development of more sophisticated cooling solutions to meet increasing performance demands. Incorporating lifestyle principles such as ergonomic design can further improve device usability and comfort during extended use.

By using high thermal conductivity materials like copper and ultra-thin vapor chamber designs (~0.20 mm), heat spreads quickly from hot spots, keeping devices cool without active components. This method supports compact, lightweight designs by removing bulky heatsinks and active cooling parts. The integration of advanced materials can further optimize thermal performance and durability.

It also adapts well to irregular or curved surfaces, offering design flexibility. With no moving parts, edge cooling ensures silent operation and boosts reliability, making it ideal for sensitive or space-constrained electronics. Additionally, understanding heat transfer principles helps optimize the design and effectiveness of edge-cooling solutions.

How Passive Heat Dissipation Works in Modern Devices

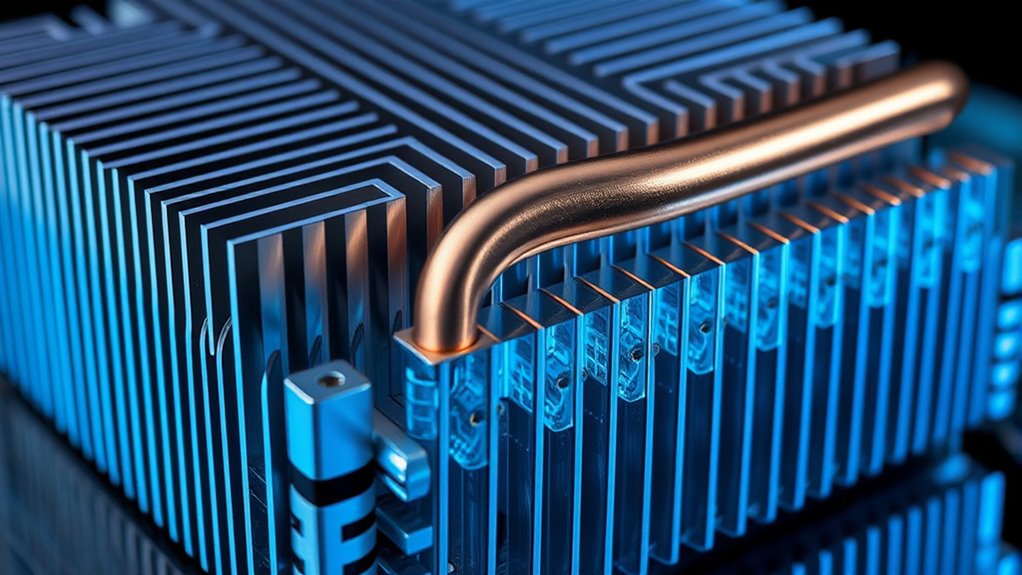

Modern devices rely on passive heat dissipation methods that leverage high thermal conductivity materials like copper and aluminum to transfer heat away from sensitive components. These materials efficiently conduct heat, helping prevent overheating without active cooling. In addition, the use of high-thermal conductivity materials enhances color accuracy by maintaining stable operating temperatures that prevent thermal-induced distortions. Heat sinks, often with finned designs, increase surface area to enhance heat transfer through conduction and convection. Vapor chambers and heat pipes use phase change principles—liquid evaporation and condensation—to move heat quickly across small distances, maintaining even temperatures. Their thin profiles, around 0.20 mm, make them flexible and space-efficient. Proper device layout, natural airflow, and reflective or insulating materials further improve passive cooling. These strategies also benefit device longevity by reducing thermal stress on components, thus extending their operational lifespan. Additionally, advancements in thermal interface materials improve the efficiency of heat transfer between components and heat sinks. Moreover, ongoing research into advanced materials continues to push the boundaries of passive cooling capabilities. Together, these strategies optimize heat transfer, keeping devices cool without fans and ensuring reliable performance.

The Role of Advanced Materials in Fanless Cooling Systems

Advanced materials play a vital role in fanless cooling by enhancing heat transfer and flexibility. High thermal conductivity metals like copper and aluminum rapidly dissipate heat. Lightweight, flexible materials such as graphene conform to device surfaces. Incorporating these innovations leads to more efficient, durable edge-cooling solutions without the need for fans. Additionally, understanding ethical hacking principles can help in safeguarding these advanced cooling systems from cybersecurity threats. Recognizing the importance of material science can further drive the development of innovative cooling technologies. Exploring sustainable material development can also contribute to more environmentally friendly cooling solutions.

High Thermal Conductivity Materials

High thermal conductivity materials play an essential role in fanless cooling systems by efficiently transferring heat away from electronic components without the need for active fans. Materials like copper, aluminum, and advanced composites boast high thermal conductivity, enabling rapid heat dissipation.

Vapor chambers made from ultra-thin, flexible materials with thermal conductivity around 400 W/m·K spread heat evenly across surfaces, preventing hotspots. Phase change materials (PCMs) integrated into vapor chambers and heat pipes facilitate swift heat transfer through melting and solidification cycles, enhancing cooling performance. Understanding thermal conductivity is crucial for designing effective fanless cooling solutions, especially as advanced materials continue to evolve to meet the demands of compact electronic devices.

Emerging composite materials that combine ceramics and metals, along with thermally conductive polymers and graphene-based substances, offer lightweight, durable, and highly efficient options. These innovations are essential for maintaining optimal device temperatures while minimizing size and noise. Incorporating thermal management techniques is vital for optimizing the performance of modern fanless cooling systems, ensuring devices operate reliably under various conditions. Additionally, ongoing research into material interfaces improves heat transfer efficiency between components, further enhancing cooling performance.

Flexible, Lightweight Components

Flexible, lightweight components made from cutting-edge materials are transforming fanless cooling systems by allowing heat management solutions to conform seamlessly to complex device geometries. These advanced materials, like high-thermal-conductivity composites, enable vapor chambers and heat sinks to bend around curves, supporting compact designs. These materials also contribute to thermal efficiency by facilitating rapid heat transfer across irregular surfaces. Additionally, the use of advanced materials enhances durability and longevity of cooling components in various environments. Innovative material engineering techniques further optimize these properties for specific applications. Thin-film materials such as graphene and flexible metal foils enhance flexibility and thermal performance, ensuring efficient heat transfer without adding bulk. Lightweight, durable materials reduce the overall weight of cooling components, making them ideal for portable and wearable electronics. The integration of flexible electronics with these materials further broadens the potential for innovative cooling solutions in modern devices. Here’s a visual of these innovations: The role of advanced materials in fanless cooling systems.

Comparing Edge‑Cooling Solutions to Traditional Fans

When comparing edge-cooling solutions to traditional fans, you’ll notice that edge-cooling provides a quieter, more compact alternative for heat management. Unlike fans that rely on active airflow, passive cooling methods like vapor chambers excel at heat transfer through conduction and radiation, reducing mechanical failure points. Community engagement in the development of these technologies fosters innovation and practical improvements. These solutions often achieve profiles as thin as 0.20 mm, making them ideal for space-constrained devices such as wearables and small electronics. Vapor chambers also have higher thermal conductivity than metal heatsinks alone, enabling rapid heat spreading without moving parts. Additionally, fan alternatives typically consume less power and generate less noise, making them perfect for quiet, portable, and sensitive environments. Passive cooling techniques contribute to increased device longevity by reducing wear and tear on moving components. Moreover, advancements in thermal management are continuously expanding the applications of edge-cooling technologies. Thermal conductivity is a key factor that enhances the efficiency of vapor chambers and other passive cooling solutions. The use of phase-change materials further enhances the efficiency of these cooling solutions by providing temporary heat absorption during peak loads. Overall, edge-cooling delivers efficient, silent cooling in a smaller, more reliable package compared to traditional fans.

Key Components of Fanless Cooling: Heat Sinks, Heat Pipes, and Vapor Chambers

You’ll want to understand how heat sinks, heat pipes, and vapor chambers work together to maximize cooling efficiency without fans.

Their material choices and design features play a vital role in transferring heat effectively from components. By optimizing these elements, you can improve thermal management while keeping systems quiet and reliable.

Heat Dissipation Efficiency

Heat dissipation efficiency in fanless cooling systems relies on a combination of key components designed to transfer heat effectively without moving parts. These components maximize passive cooling by utilizing conduction, phase change, and thermal spreading. Heat sinks increase surface area with fins of metals like aluminum or copper, enhancing heat transfer through conduction. Heat pipes contain a liquid that evaporates at the hot end and condenses at the cooler end, rapidly moving heat away. Vapor chambers are thin, highly conductive spreaders that use vaporization and condensation within a sealed chamber, offering superior heat transfer efficiency. Their flexibility and minimal thickness improve thermal contact with various device geometries, optimizing heat dissipation.

| Component | Function |

|---|---|

| Heat Sink | Conducts heat away via fins |

| Heat Pipe | Transfers heat through phase change |

| Vapor Chamber | Spreads heat efficiently, conforming to surfaces |

Material and Design Choices

Selecting the right materials and designing components effectively are vital for optimizing fanless cooling systems. Material choice directly influences thermal conductivity, which determines how efficiently heat transfers away from hot components.

For heat sinks, high thermal conductivity metals like aluminum or copper are common, with copper offering higher conductivity but at a greater weight and cost.

In heat pipes and vapor chambers, design features such as microchannels and wicking structures enhance fluid flow and heat transfer.

Vapor chambers are thin, flat heat spreaders that conform to curved surfaces, ensuring uniform heat distribution.

The design and material choice work together to maximize thermal performance, minimize size, and support the device’s form factor. Proper selection of both elements is essential for effective, silent cooling solutions.

Innovations in Vapor Chamber Design and Their Impact

Recent innovations in vapor chamber design are transforming thermal management by enabling more compact, flexible, and efficient cooling solutions. Modern vapor chambers like DNP’s models feature ultra-thin profiles around 0.20 mm, allowing integration into curved and space-constrained devices for effective heat spreading.

These chambers utilize phase-change heat transfer, offering higher thermal conductivity and faster heat dissipation than traditional heat sinks and pipes. Innovative designs incorporate flexible materials that bend and conform to irregular shapes, supporting device miniaturization and versatile form factors.

Improvements in manufacturing materials and structures have boosted thermal performance, enabling higher power densities in portable electronics. When combined with other passive cooling components, vapor chambers create silent, efficient thermal management solutions suitable for fanless systems, making device cooling more seamless and reliable.

Practical Applications of Edge‑Cooling in Portable and Compact Devices

Innovations in vapor chamber design are now enabling practical edge-cooling solutions that fit seamlessly into portable and compact devices. These solutions leverage high thermal conductivity to efficiently spread heat across thin, flexible surfaces, minimizing hot spots without increasing size.

As a result, you can enjoy improved performance and longer device lifespan in space-constrained gadgets. Edge-cooling components, often around 0.20 mm thick, can bend around curved surfaces, making them perfect for wearables, smartphones, and other portable devices.

Key benefits include:

- Enhanced thermal management through phase change processes

- Reduced reliance on internal fans, enabling silent operation

- Support for device miniaturization and sleek design

- Passive cooling that maintains optimal temperatures without extra power

This technology delivers cooler, quieter, and more reliable portable devices without adding bulk.

Future Trends and Challenges in Fanless Device Cooling

Advancements in fanless device cooling are increasingly driven by the development of advanced vapor chamber materials with thermal conductivities exceeding 400 W/m·K, aiming to enhance heat dissipation in ultra-compact electronics. These innovations improve thermal management by enabling more efficient passive cooling solutions.

However, scaling vapor chamber technology for high-power applications, like GPUs, remains a challenge without increasing device size or cost. Flexible, foldable vapor chambers open new possibilities for irregularly shaped and wearable devices, pushing passive cooling boundaries.

Integrating thermoelectric modules with vapor chambers offers localized cooling but faces hurdles in power efficiency and miniaturization. Developing cost-effective manufacturing processes for nano-structured heat transfer materials is essential to making advanced vapor chamber passive cooling practical and widespread in future fanless device designs.

Frequently Asked Questions

How Can I Keep My CPU Cool Without a Fan?

If you’re wondering how to keep your CPU cool without a fan, consider using advanced cooling methods like vapor chambers and edge-cooling solutions. These passive systems transfer heat efficiently through phase change and conduction.

They dissipate heat at the device’s edges. By combining high-conductivity materials and strategic heat sink placement, you can maintain safe CPU temperatures without noise or moving parts.

This approach keeps your device cool and silent, even under load.

How Do You Keep Cool When You Don’t Have a Fan?

When you don’t have a fan, you can keep cool by using passive cooling methods. Place your device in a well-ventilated area, elevate it to improve airflow, and avoid direct sunlight.

Use heat sinks or vapor chambers to spread heat efficiently.

Open windows or create cross-ventilation to let natural air flow cool your space. These strategies help dissipate heat without relying on active cooling devices.

How Do Phones Stay Cool Without Fans?

Think of your phone as a busy highway, where heat is the traffic that needs to flow smoothly. You stay cool without a fan because advanced heat spreaders like vapor chambers and heat pipes act like traffic cops, guiding heat away efficiently.

High-conductivity materials like graphene help spread heat evenly. These passive cooling methods keep your device running smoothly, preventing overheating without the noise or power drain of fans.

How Do Fanless Laptops Stay Cool?

You might wonder how fanless laptops stay cool without fans. They rely on advanced passive cooling methods, like vapor chambers and heat pipes, which transfer heat efficiently away from components through conduction and radiation.

These devices use high thermal conductivity materials like copper and aluminum, along with strategic component placement and compact heat sinks.

Proper venting and ambient temperature management further help prevent overheating, keeping your laptop running smoothly.

Conclusion

So, next time your device stays cool without a noisy fan, remember it’s probably just quietly plotting to outsmart traditional cooling methods. Edge‑cooling tech proves you don’t need a mini jet engine inside your gadget—just clever materials and smart design. Soon, your phone might chill better than a snowman in summer, all while you bask in the silence. Who knew staying cool could be so sneaky, silent, and downright impressive?