When troubleshooting a pressure pool cleaner, first check that water flow and pressure are adequate by inspecting the pump and skimmer baskets for obstructions. Next, clean and inspect the intake, nozzles, and hoses for debris or leaks. Make sure the cleaner’s position and alignment are correct, and verify the drive mechanism and wheels are functioning smoothly. Replacing damaged seals or parts may be necessary. Following these steps can help solve common issues and keep your cleaner running efficiently.

Key Takeaways

- Check water pressure with a gauge; ensure it’s within the 30-50 psi range for optimal cleaner performance.

- Inspect and clean hoses, intake screens, and nozzles to prevent blockages and maintain proper water flow.

- Verify that all hose connections are secure, leak-free, and free of kinks or damage affecting pressure.

- Examine the drive wheels, gears, and belts for wear or misalignment; replace or adjust as needed.

- Ensure the cleaner is properly positioned in the pool center, away from obstructions, for even coverage and effective cleaning.

Checking the Water Pressure and Flow Rate

Before troubleshooting your pressure pool cleaner, it’s essential to check the water pressure and flow rate. Start by observing the water flow from the cleaner’s return jets; weak or inconsistent flow indicates a problem. Use a pressure gauge on the pool’s skimmer or pump to measure the pressure; it should typically be between 30 and 50 psi. If the pressure gauge shows low readings, your cleaner may not have enough force to operate correctly. Conversely, excessively high pressure can signal a blockage or closed valve. Ensuring proper water flow and vital pressure is crucial before inspecting other components. Adjusting valves or clearing obstructions can often resolve pressure issues, restoring your pressure pool cleaner’s efficiency. Additionally, understanding water flow and how it affects equipment performance can help prevent future issues. Proper pump operation also plays a significant role in maintaining consistent pressure levels. Regular maintenance and monitoring can help maintain optimal system performance and prevent unexpected breakdowns.

Inspecting and Cleaning the Intake and Nozzles

To guarantee your pressure pool cleaner operates efficiently, you should inspect and clean its intake and nozzles regularly. Start by removing any debris or buildup that may clog the intake to secure proper water flow. During filter maintenance, check the intake screen for dirt or obstructions and clean it thoroughly. Next, examine the nozzles for blockages or misalignment; clean them with a small brush if needed. Proper nozzle alignment is vital for maximum cleaning performance, so adjust as necessary to ensure water jets are directed correctly. Keeping the intake and nozzles clean and properly aligned prevents pressure drops and improves overall efficiency. Additionally, inspecting components like pressure regulation can help maintain optimal operation and prevent unnecessary wear. Regularly checking pump performance can further ensure your cleaner maintains consistent pressure and cleaning effectiveness.

Examining the Hoses and Connections for Leaks or Blockages

Start by inspecting your hoses for any signs of leaks, cracks, or loose fittings that could disrupt pressure. Next, check for obstructions or blockages inside the hoses that might hinder water flow. Ensuring both the integrity and clarity of the hoses helps your cleaner operate smoothly. Additionally, verifying that the hoses maintain proper pressure levels can prevent performance issues. Regularly inspecting and maintaining tableware materials used nearby can also prevent accidental damage or contamination that could affect the pool cleaner’s operation.

Inspect Hose Integrity

Inspecting the hoses and connections is a crucial step in troubleshooting your pressure pool cleaner, as leaks or blockages here can greatly reduce its effectiveness. Check for hose degradation, such as cracks, brittleness, or soft spots, which can cause leaks or weak connections. Examine each hose for signs of wear and replace any damaged sections. Confirm all connections are secure and stable; loose or worn-out fittings can lead to pressure loss. Tighten any loose clamps or fittings, and replace any worn or damaged connectors. Verify that hoses are free from kinks or sharp bends that could restrict water flow. Maintaining hose integrity and connection stability ensures your cleaner operates efficiently and prevents pressure issues that hinder cleaning performance. Regularly inspecting for hose degradation can help prevent unexpected failures during operation. Additionally, inspecting connection fittings for corrosion or damage can ensure optimal water flow and pressure. Ensuring proper clamp tightness can prevent accidental disconnections and improve overall efficiency. Properly inspecting and maintaining connection integrity is essential for consistent cleaning results and prolongs the lifespan of your pressure pool cleaner. Also, checking for any clogged fittings can help maintain steady water pressure and cleaning effectiveness.

Check for Obstructions

Have you checked your hoses and connections for obstructions that could be blocking water flow? Leaf debris and algae buildup are common culprits that can cause clogs, reducing pressure and preventing your cleaner from functioning properly. Inspect all hoses thoroughly, looking for any kinks, cracks, or leaks that could impair water movement. Remove any debris or algae buildup you find, ensuring the connections are secure and free of blockages. Sometimes, small leaves or algae can get trapped inside the hoses, creating a partial or complete blockage. Clearing these obstructions restores proper water flow, helping your pressure pool cleaner work efficiently. Regularly checking and maintaining your hoses prevents future issues and keeps your pool cleaner operating smoothly. Additionally, hose maintenance is essential for ensuring your cleaner continues to perform at its best, especially since the water flow can be affected by any irregularities in the hoses or connections. Proper filter cleaning can also improve overall system performance and prevent clogs caused by debris buildup. Moreover, understanding the importance of skimmer baskets can help minimize debris entering the system and reduce potential blockages. Regular inspections of all these components help prevent robotics expansion issues that can arise from unnoticed obstructions or damage.

Ensuring Proper Installation and Positioning of the Cleaner

To guarantee your pressure pool cleaner operates effectively, proper installation and positioning are vital. Ensure the cleaner is securely attached to the hose and placed in the optimal spot for coverage. Correct positioning depends on water flow, which can be affected by pool chemical balance and water temperature. For example, unbalanced chemicals can cause debris buildup, while cold water can slow the cleaner’s movement. Use the table below to help you position your cleaner effectively:

| Positioning Tip | Why It Matters | Best Practice |

|---|---|---|

| Attach hose securely | Prevents leaks and loss of pressure | Check connections before use |

| Place cleaner in center | Ensures even coverage | Avoid corners and obstructions |

| Check water flow | Maintains proper movement | Adjust skimmer and return jets if needed |

| Monitor chemical levels | Keeps debris from sticking | Balance pool chemicals regularly |

| Adjust for water temp | Maintains optimal operation | Use pool heaters if water is too cold |

Additionally, understanding the importance of water flow and how it impacts the cleaner’s performance can help you troubleshoot and optimize your pool cleaning process. Proper water flow is essential for maintaining pressure and ensuring the cleaner moves efficiently across the pool surface.

Verifying the Skimmer and Pump Basket for Obstructions

Since obstructions in the skimmer and pump basket can disrupt water flow and hinder your pressure cleaner’s performance, it’s essential to verify that these components are clear. Start by turning off your pool’s pump and removing the skimmer basket. Check for leaves, debris, or any buildup that could restrict flow. Clean out the skimmer basket thoroughly, ensuring all debris is removed. Next, access the pump basket, which sits near the pump itself. Empty any debris and rinse the basket with water to remove dirt and debris. A clogged skimmer or pump basket reduces water flow, causing the pressure cleaner to operate inefficiently or stop altogether. Regularly inspecting and cleaning these baskets keeps water flowing smoothly and maintains ideal cleaning performance. Additionally, using proper professional equipment ensures the best results when cleaning and inspecting these components. Incorporating self-watering plant pots into your pool area can also help manage moisture and reduce debris accumulation around the pool equipment.

Testing the Drive Mechanism and Wheels

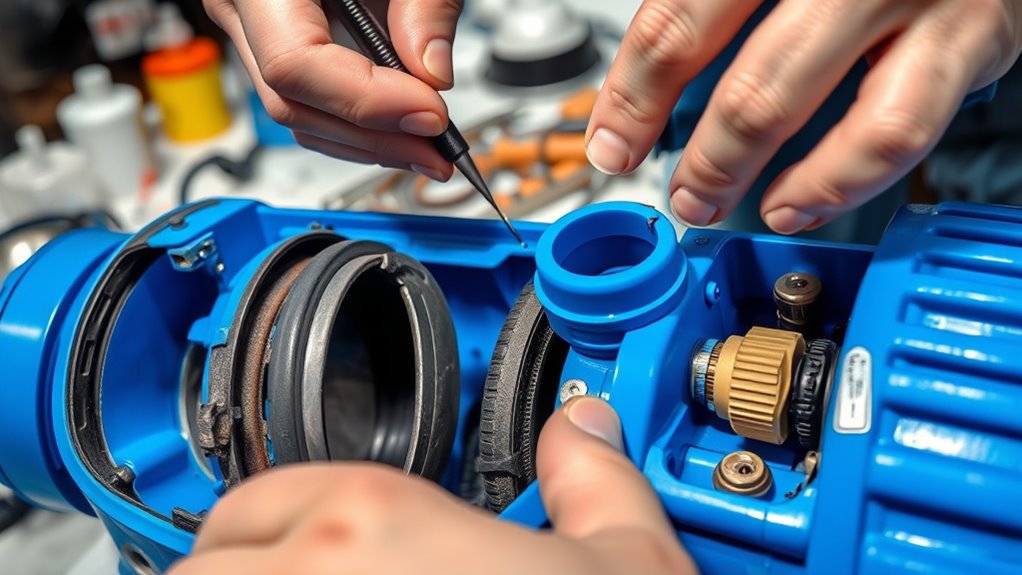

If your pressure pool cleaner isn’t moving properly, testing the drive mechanism and wheels is a crucial step. Start by inspecting the drive mechanism for any visible damage or obstructions that could hinder movement. Ensure that the drive gear is functioning smoothly and engaging correctly. Next, check the wheels for proper wheel alignment; misaligned wheels can cause uneven cleaning or stalling. Spin each wheel manually to see if they turn freely without resistance or wobbling. If you notice any misalignment or the wheels don’t rotate smoothly, adjust or replace them as needed. Proper drive mechanism operation and wheel alignment are essential for your cleaner to navigate your pool effectively. Addressing these issues often restores proper movement and improves cleaning performance.

Assessing the Condition of the Drive Belt or Motor Components

Next, examine the drive belt and motor components for signs of wear or damage. Begin with a thorough drive belt inspection, checking for cracks, fraying, or slack that could impair performance. If the belt appears worn or brittle, it likely needs replacement. During motor component evaluation, look for any corrosion, burnt smells, or unusual noises that suggest motor issues. Inspect the motor shaft and connections for looseness or debris buildup. Ensure the belt is properly aligned and tensioned. A damaged or misaligned drive belt can cause slipping or failure to turn the wheels. Similarly, compromised motor components might lead to reduced power or complete failure. Regularly evaluating these parts helps prevent breakdowns and keeps your pool cleaner operating smoothly.

Replacing or Repairing Damaged Parts and Seals

You may notice leaks or a drop in pressure, which often indicate worn seals or damaged parts. Replacing these components quickly restores your cleaner’s performance and prevents further issues. Let’s go over how to identify and swap out the faulty seals and parts effectively.

Identifying Worn Seals

Worn or damaged seals are a common cause of pressure pool cleaner malfunctions, and identifying them early can save you time and money. Over time, seal degradation occurs due to constant exposure to water, chemicals, and wear. Look for signs like leaks around the seal area, reduced suction, or inconsistent cleaning. Carefully inspect the seals for cracks, tears, or hardening, which indicate they’ve become brittle or deformed. If you notice any damage or deterioration, seal replacement is necessary to restore proper function. Regularly checking your seals prevents bigger issues down the line. By keeping an eye on their condition, you ensure your pressure pool cleaner operates efficiently and avoids unnecessary repairs caused by overlooked seal wear.

Replacing Damaged Parts

When you notice your pressure pool cleaner isn’t functioning properly, replacing damaged parts or seals is often the most effective solution. Over time, wear and tear from seasonal maintenance or fluctuations in pool chemistry can cause components to fail. Here are four steps to help you replace damaged parts:

- Turn off the pump and drain the cleaner to prevent water damage.

- Inspect hoses, seals, and the drive belt for cracks or corrosion.

- Remove damaged parts carefully, noting how they fit.

- Install new parts, ensuring proper sealing and connection.

Regularly checking and replacing worn parts keeps your cleaner running smoothly and extends its lifespan. Staying on top of pool chemistry and seasonal maintenance minimizes damage and improves cleaning efficiency.

Maintaining Regular Cleaning and Preventative Checks

Regular cleaning and preventative checks are indispensable for keeping your pressure pool cleaner operating efficiently and preventing costly repairs. You should regularly inspect the pool’s chemical balance to ensure proper sanitation and avoid buildup that can clog or damage the cleaner. Maintaining the correct chemical levels also helps keep the pool water clear and safe. Additionally, pool cover maintenance is crucial; a clean, properly fitted cover prevents debris from entering the water, reducing the strain on your cleaner. Periodically verify that the hoses and connections are secure and free of leaks. By staying on top of these tasks, you’ll extend your cleaner’s lifespan and ensure it works effectively, saving you time and money while keeping your pool pristine.

Frequently Asked Questions

How Often Should I Service My Pressure Pool Cleaner?

You should follow a regular maintenance schedule to keep your pressure pool cleaner running smoothly. Typically, inspect and clean it weekly, especially the brushes and nozzles. Replace parts like hoses or brushes as needed, usually every couple of seasons or sooner if worn. Regular maintenance prevents breakdowns and extends its lifespan, ensuring your pool stays clean and clear. Staying proactive with your upkeep saves you time and money in the long run.

What Safety Precautions Are Necessary During Maintenance?

When maintaining your pressure pool cleaner, prioritize safety by wearing appropriate safety gear like gloves and goggles to protect yourself from debris and chemicals. Always turn off the power supply to guarantee electrical safety before working on the equipment. Keep the area dry to prevent slips and electrical hazards. Following these precautions helps you stay safe, avoid injuries, and ensures your maintenance process is smooth and effective.

Can I Use My Pressure Cleaner in All Pool Types?

Using your pressure cleaner on every pool type might seem like a no-brainer, but it’s not that simple. You need to check the pool’s chemical balance first—imagine trying to clean a pool with a super sour or slimy water mess! Also, don’t forget to clean the skimmer basket; it’s like giving your cleaner a fresh start. Not all pools are created equal, so double-check compatibility for perfect cleaning.

What Signs Indicate a Need for Professional Repair?

If your pressure pool cleaner shows signs like persistent leaks, unusual noises, or inconsistent movement, it’s time for professional repair. Leak detection can reveal hidden cracks or worn hoses, while motor troubleshooting helps identify electrical or mechanical issues. Don’t ignore these signs—prompt professional help guarantees your cleaner works efficiently and prevents further damage, saving you time and money in the long run.

How Do Weather Conditions Affect Cleaner Performance?

Weather impact and seasonal changes can considerably affect your pool cleaner’s performance. Cold weather may slow down or freeze components, while heat can cause parts to wear faster. Wind and rain can introduce debris or disrupt suction, making it harder for your cleaner to do its job. You should regularly check your cleaner after weather events, ensuring it’s clean and functioning properly to maintain ideal performance throughout seasonal changes.

Conclusion

By paying attention to these simple steps, you’ll keep your pool cleaner running smoothly and enjoying its quiet, diligent work. Regular check-ins help prevent minor hiccups from becoming bigger issues, allowing you to focus on the true pleasure of a sparkling pool. Think of it as gentle nurturing—caring for your cleaner guarantees it continues to serve you well, making pool maintenance feel less like a chore and more like a relaxing routine.