To care for your pressure pool cleaner during the off-season, disconnect and clean all parts thoroughly. Inspect hoses, seals, and brushes for wear or damage, replacing any worn components. Flush the system with clean water to remove debris and chemicals, then drain and dry everything completely. Store your equipment in a dry, cool place, and lubricate moving parts to guarantee longevity. If you’d like detailed steps, there’s more to learn.

Key Takeaways

- Disconnect, clean, and thoroughly dry all components before storage to prevent mold, corrosion, and damage.

- Inspect hoses, fittings, and electrical parts for wear or damage; replace as needed to ensure readiness.

- Store equipment in a cool, dry, and pest-free environment, elevated off the ground in sealed containers.

- Flush internal parts and hoses with water to remove debris, algae, and residual chemicals.

- Perform a final inspection and run the cleaner to verify proper operation before the next season.

Disconnecting and Cleaning the Pressure Pool Cleaner

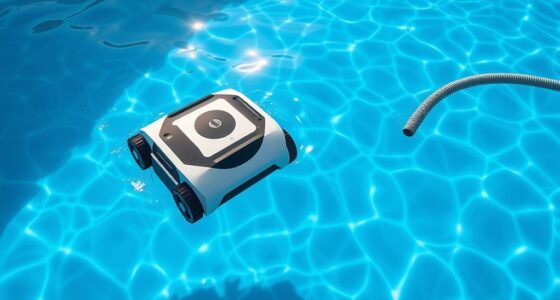

Before storing your pressure pool cleaner for the off-season, it’s essential to disconnect it properly and give it a thorough cleaning. Start by turning off the pump and unplugging the cleaner to ensure safety. Next, detach the hose and any removable parts, inspecting for wear or damage. Clean all components with fresh water, paying attention to remove dirt, debris, and residual chemicals that could affect pool safety later. Maintaining proper chemical balance in your pool is crucial during this process to prevent algae growth or corrosion. Wiping down the cleaner helps prevent buildup that could damage it over time. Proper cleaning and disconnection not only prolong the life of your pressure pool cleaner but also ensure your pool remains safe and chemically balanced for future use. Additionally, implementing automation’s role in business intelligence can help monitor equipment status and optimize maintenance schedules for your pool equipment. Regular maintenance and preventive care can further extend the longevity of your pool cleaning system and ensure optimal performance when you reopen your pool. Incorporating routine inspections can also help identify potential issues early, reducing repair costs and downtime. Performing consistent upkeep according to manufacturer guidelines enhances the overall durability and efficiency of your pressure pool cleaner. Moreover, understanding pressure system components can aid in troubleshooting any operational issues efficiently.

Inspecting and Replacing Worn Parts

After cleaning and disconnecting your pressure pool cleaner, take the time to inspect all parts for signs of wear or damage. Check hoses, clamps, and fittings for cracks, leaks, or deterioration. Replace worn or cracked hoses promptly to prevent malfunctions. Inspect the filter; if it’s dirty or damaged, perform a filter replacement to ensure thorough cleaning and water flow. Examine the electrical components for signs of corrosion or frayed wires, and prioritize electrical safety by unplugging the unit before inspection. Ensure all connections are secure and that no parts are loose. Regularly referencing filter maintenance guidelines can help you identify issues early and maintain optimal performance. Keeping an eye on pressure pool cleaner components can also help you troubleshoot issues more effectively, including recognizing electrical safety concerns that could lead to hazards. Performing routine system checks can further help prevent unexpected breakdowns and prolong the life of your equipment. Replacing worn parts now helps prevent breakdowns during the next season and keeps your pool cleaner operating efficiently. Proper inspection and timely replacement extend the lifespan of your pressure pool cleaner.

Flushing the System to Remove Debris and Chemicals

To guarantee your pressure pool cleaner operates efficiently in the upcoming season, it’s essential to flush the system thoroughly. Begin by disconnecting the cleaner and running clean water through the hoses and internal components. This process helps with debris removal, preventing clogs and buildup that could impair performance. While flushing, pay attention to the chemical balance within the system, ensuring no residual chemicals remain that could damage parts or interfere with future use. Use a hose to rinse out all chambers and connections, removing dirt, algae, and chemical residues. Proper flushing ensures your pressure pool cleaner is clean, debris-free, and ready for the next season. Regularly performing this step can extend the lifespan of your equipment and maintain optimal cleaning efficiency. Additionally, incorporating system maintenance practices can help identify potential issues early and ensure your equipment remains in top condition. Implementing preventative maintenance routines can further reduce the likelihood of unexpected failures. Advances in machine learning algorithms can also assist in diagnosing potential issues with your pool system to prevent future problems.

Properly Draining and Drying the Equipment

Before storing your pressure pool cleaner, make sure to drain all the water completely. This prevents freezing and damage during the off-season. Additionally, make certain the equipment is thoroughly dried to avoid mold and corrosion. Proper drying helps maintain the durability of equipment, ensuring their longevity and effectiveness. Proper drying also reduces the risk of nutrient buildup, which can lead to mold or bacterial growth. Incorporating sound vibrations during drying can enhance cellular regeneration and help eliminate residual moisture more effectively. Furthermore, inspecting and replacing worn parts can prevent future malfunctions and extend the lifespan of your cleaner. Regular maintenance and cleaning during off-season periods can also improve overall performance when in use again.

Drain Completely Before Storage

Ensuring your pressure pool cleaner is completely drained before storage is essential to prevent damage from residual water. Water left inside can cause mold, corrosion, or freezing damage during seasonal maintenance. To avoid this, disconnect hoses and remove any fittings or brushes, then tilt or shake the cleaner to release trapped water. Additionally, make sure that all parts are dry to prevent mold growth. Use this simple table to guide your process:

| Step | Action | Purpose |

|---|---|---|

| Drain hoses | Remove water from hoses | Prevent freezing and mold |

| Remove residual water | Shake or tilt cleaner | Avoid corrosion and damage |

| Dry thoroughly | Wipe with dry cloth | Prepare for storage |

Proper draining and drying protect your equipment, ensuring it’s ready for next season’s chemical treatments and seasonal maintenance. Headphones can be a helpful tool to listen for any residual moisture or to enjoy music while cleaning and storing your equipment.

A thorough check for water retention can help identify any hidden moisture that might cause issues later.

Ensure Thorough Drying

After draining your pressure pool cleaner, it’s essential to dry all parts thoroughly to prevent mold, corrosion, and freezing damage. Make certain no residual water remains, as trapped moisture can compromise the equipment’s chemical stability over time. Use compressed air or a clean towel to dry internal and external components completely. Proper drying also helps maintain equipment calibration, ensuring consistent cleaning performance when you resume use. Pay special attention to hoses, fittings, and motor areas, as moisture in these parts can lead to corrosion and malfunction. Storing the cleaner with dry, stable conditions preserves its integrity and extends its lifespan. Taking these steps guarantees your pressure pool cleaner stays in top condition, ready for effective operation when the season begins again.

Storing in a Suitable Location

Choosing the right storage location for your pressure pool cleaner is essential to keep it in good condition during the off-season. Select a cool, dry spot away from direct sunlight to maintain proper temperature regulation and prevent damage. Make certain the area is free from pests that could chew or nest in your equipment. Consider these tips:

- Store in a climate-controlled space to avoid extreme temperature fluctuations.

- Keep it off the ground to prevent moisture exposure and pest access.

- Use sealed containers or covers to protect against dirt, dust, and pests.

Lubricating Moving Parts for Longevity

Regularly lubricating the moving parts of your pressure pool cleaner is essential for keeping it operating smoothly and extending its lifespan. Proper lubrication techniques help reduce friction and prevent wear on components like gears, wheels, and hinges. To maintain your cleaner’s moving part maintenance, use a silicone-based or water-resistant lubricant recommended by the manufacturer. Apply a small amount to pivot points, axles, and other moving joints, ensuring even coverage. Avoid over-lubricating, as excess can attract dirt and debris. Regular lubrication not only keeps your cleaner functioning efficiently but also helps prevent costly repairs down the line. Incorporate this simple step into your off-season care routine to ensure your pressure pool cleaner remains in top condition for the next pool season.

Checking Hoses and Connections for Damage

Inspecting your pressure pool cleaner’s hoses and connections for damage is a crucial step in off-season maintenance. Confirming hose integrity and connection security prevents leaks and malfunctions when you restart it. First, check hoses for cracks, holes, or brittleness that could compromise their function. Next, examine all connections to confirm they’re tight and secure, avoiding leaks. Finally, look for any signs of wear or damage at connection points, replacing parts if needed. Remember, damaged hoses or loose connections can reduce cleaning efficiency and cause equipment failure. Regular inspection helps maintain ideal hose integrity and connection security. Taking these simple steps now ensures your pressure pool cleaner stays in top shape, ready for hassle-free use when the season begins again.

Performing a Pre-Season Inspection Before Use

Before firing up your pressure pool cleaner, give it a thorough pre-season inspection. Check all components visually for cracks or damage, run the unit to guarantee it operates smoothly, and verify that wear parts like brushes and seals are in good shape. Replacing any worn or damaged parts now will keep your cleaner running efficiently all season long.

Visual Inspection of Components

A thorough visual inspection of your pressure pool cleaner’s components is essential before the season begins to guarantee peak performance and prevent potential issues. Begin by checking for any visible damage or wear on parts like brushes, hoses, and seals. Next, focus on these key areas:

- Ensure sensors are clean and properly calibrated to maintain accurate navigation and cleaning efficiency.

- Inspect electrical connections for corrosion, frayed wires, or loose fittings to ensure electrical safety.

- Look for cracks or damage on the housing and moving parts, replacing any compromised components.

Addressing these issues early helps avoid costly repairs later. Proper sensor calibration ensures optimal operation, while verifying electrical safety prevents hazards. A diligent visual check sets the stage for a smooth, effective cleaning season.

Test Run and Functionality

Performing a test run is an essential step to guarantee your pressure pool cleaner functions correctly before the season starts. Before turning it on, check that the pool’s water chemistry is balanced, as improper levels can affect cleaning performance. Also, verify the water temperature is within the cleaner’s ideal range, since extreme temperatures can cause malfunctions. When you run the cleaner, observe its movement and listen for unusual noises that could indicate issues. Confirm that the brushes and nozzles are moving smoothly and that water flows properly through the system. This initial check helps identify any problems early, saving you time and effort during regular maintenance. A successful test run ensures your pressure pool cleaner will operate efficiently throughout the season.

Check and Replace Wear Parts

Regularly inspecting and replacing wear parts is crucial to guarantee your pressure pool cleaner operates at peak efficiency. During seasonal maintenance, check all components like hoses, seals, and brushes for signs of wear or damage. Worn parts can impair cleaning performance and affect pool chemistry by allowing debris to circulate. To ensure smooth operation, consider these steps:

- Inspect all moving parts for cracks or deterioration.

- Replace worn brushes, seals, or hoses to maintain ideal cleaning.

- Test the cleaner’s functionality before pool season starts to avoid surprises.

Maintaining the Pool Environment During Off-Season

Ever wondered how to keep your pool in top shape during the off-season? Keeping the pool environment balanced is vital. First, make sure you adjust your pool chemicals properly—chlorine or alternative sanitizers should be maintained at recommended levels to prevent algae growth and bacteria buildup. Lower the water level slightly if your pool is exposed to freezing temperatures, but avoid completely draining it. Regularly skim the surface to remove debris, and consider using a pool cover to block dirt and sunlight. Algae prevention is essential; adding algaecide before closing helps reduce future algae blooms. Proper chemical balance and cleanliness during the off-season protect your pool’s equipment and make opening easier when swim season resumes.

Frequently Asked Questions

How Often Should I Perform Off-Season Maintenance on My Pressure Pool Cleaner?

You should perform off-season maintenance on your pressure pool cleaner at least once a year. Follow winterization tips to protect it from freezing temperatures, ensuring you clean and inspect all parts thoroughly. Use storage precautions like draining hoses and storing the unit in a dry, sheltered area. Regular maintenance helps prevent damage, extends the cleaner’s lifespan, and keeps it ready for quick use when swimming season starts again.

Can I Leave Chemicals in the System During Storage?

You can leave some chemicals in the system during storage, but it’s best to minimize chemical residue to prevent damage. Always follow storage precautions, like draining water and cleaning filters, to avoid corrosion or mold growth. If you choose to leave chemicals, use a stabilizer or algaecide in small amounts. However, it’s safer to drain and thoroughly clean your pressure pool cleaner to keep it in top shape for the next season.

What Are Signs That My Pressure Cleaner Needs Repairs Before Storage?

Think of your pressure cleaner like a car before winter—if it shows trouble indicators, it’s time for a repair checklist. Watch for leaks, strange noises, or reduced pressure, which signal it needs fixing. Addressing these issues beforehand guarantees smooth operation later. If you ignore these signs, problems could worsen during storage, making repairs more costly. Always inspect your cleaner thoroughly to prevent surprises when you restart pool season.

Is It Necessary to Disassemble the Cleaner Completely for Off-Season Storage?

You don’t need to fully disassemble your pressure cleaner for storage preparation. Instead, focus on cleaning and drying it thoroughly to prevent damage. A complete cleaner disassembly isn’t necessary unless you notice specific issues or plan to store it for an extended period. Proper cleaning, draining water, and protecting moving parts are key steps. This guarantees your cleaner stays in good condition and ready for use when the season begins again.

How Do I Prevent Mold or Mildew Growth During Long-Term Storage?

Think of your pressure pool cleaner as a sleeping dragon, resting safely during winter. To prevent mold and mildew growth during long-term storage, confirm it’s thoroughly cleaned and dried—like clearing a dragon’s lair of leftover dust. Use mold prevention strategies like applying a light coating of oil on metal parts and storing it in a dry, well-ventilated area. Follow these storage tips to keep it fresh and ready for next season.

Conclusion

By giving your pressure pool cleaner the TLC it deserves during the off-season, you’re fundamentally nurturing a trusty steed for many seasons to come. Think of it as tending a garden—regular care keeps everything blooming and thriving. When you store, clean, and inspect properly, you’re ensuring your cleaner will be ready to leap into action, sparkling like a star, when pool season returns. Keep up the care, and it’ll reward you with years of dependable service.