Solid-state batteries could be a game-changer for electric vehicles because they offer much higher range, improved safety, and faster charging times. With their solid electrolytes, you’ll enjoy reduced fire risks and better performance across different temperatures. Plus, they enable smaller, lighter batteries that last longer and charge faster. If you want to understand how these innovations are shaping EV future real-world benefits, keep exploring the exciting developments ahead.

Key Takeaways

- Solid-state batteries dramatically increase EV range, potentially up to 1,000 miles per charge.

- They improve safety by eliminating flammable liquid electrolytes and reducing thermal runaway risks.

- Faster charging times (10-15 minutes) are enabled, supporting high-power fast-charging without overheating.

- Higher energy density allows for smaller, lighter batteries, enhancing vehicle performance and handling.

- Industry adoption is growing, driven by safety, speed, and efficiency advantages despite current manufacturing challenges.

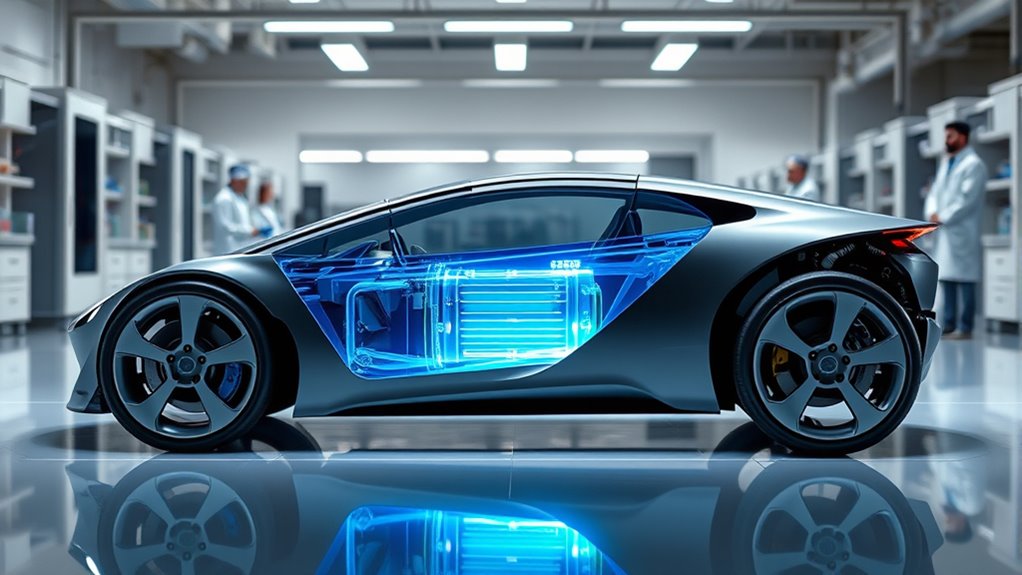

How Solid-State Batteries Enhance Vehicle Range and Performance

Solid-state batteries considerably boost vehicle range and performance by offering much higher energy densities than traditional lithium-ion batteries. You’ll see your EV’s driving range increase by 50% to 80%, with some designs aiming for up to 1,000 miles per charge. Incorporating lithium-metal anodes allows for more compact battery packs, reducing size and weight—Honda predicts these batteries will be 50% smaller and 35% lighter. This results in lighter vehicles that accelerate better and handle more responsively. The increased energy density also means you can have smaller batteries without sacrificing range. Additionally, understanding Gold IRA options can be a strategic way to diversify your investment portfolio and safeguard assets for the future. Battery technology advancements continue to drive innovation, making electric vehicles more practical and appealing. Moreover, ongoing AI security improvements are crucial to ensuring the safety and reliability of these advanced battery systems and related vehicle technologies. Overall, these improvements lead to longer trips, better efficiency, and enhanced driving experiences, making electric vehicles more practical and appealing for everyday use.

Safety Benefits Driving Adoption in Electric Vehicles

The enhanced safety features of solid-state batteries are a key factor driving their adoption in electric vehicles. Unlike lithium-ion batteries, they use solid electrolytes, which eliminate flammable liquid components, reducing fire and explosion risks. This stability under stress means fewer thermal runaway incidents, making vehicles safer. Solid electrolytes also perform well across a wider temperature range, lowering overheating hazards and simplifying thermal management. Their robust structure better withstands mechanical stress, decreasing the chances of internal damage or short circuits. Additionally, they don’t leak toxic or volatile liquids, making accidents safer for occupants and first responders. Solid electrolyte stability also contributes to consistent performance and longevity of the batteries. During crashes, solid-state batteries maintain integrity better, reducing the likelihood of fires or explosions. The collection of humorous and thought-provoking dog quotes available can also foster a positive mindset among engineers and designers working on safety innovations. Moreover, the safety benefits of these batteries can lead to stricter industry standards, encouraging widespread adoption. Improved thermal stability and safety features can further enhance consumer confidence and accelerate EV adoption, making solid-state batteries a game-changer for the industry. Additionally, the use of sustainable materials in manufacturing these batteries can support environmental goals and reduce the overall ecological footprint of electric vehicles.

Accelerating Charging and Extending Battery Lifespan

Thanks to their advanced technology, solid-state batteries enable much faster charging times—reducing a full charge from about 40 minutes to just 10-15 minutes—making quick top-ups more practical than ever. Their stable lithium plating and high current tolerance prevent dendrite growth during rapid charging, allowing for 70% faster DC fast-charging (10 minutes versus 30 for lithium-ion). Improved safety features are also a significant advantage, as thermal stability ensures high-power charging without overheating, while uniform heat distribution and passive cooling simplify thermal management. These batteries also extend vehicle range considerably—by 50-80%, targeting 900-1,000 miles—thanks to higher energy density from lithium-metal anodes and solid electrolytes. Additionally, they support thousands of charge cycles with minimal degradation, thanks to stable interfaces, resistant anodes, and durable ceramic electrolytes, ultimately improving longevity and reliability. The use of solid electrolytes enhances safety by reducing flammability risks associated with liquid electrolytes. Moreover, ongoing research in sound design techniques is helping to develop better diagnostic tools for battery health monitoring, improving maintenance and safety protocols. Advances in battery management systems are also crucial for optimizing performance and ensuring safety during operation. Furthermore, advancements in AI-powered diagnostics are playing a crucial role in predicting battery performance and preventing failures before they occur.

Industry Trends and Market Potential of Solid-State Technology

The rapid growth of the solid-state battery market reflects its strong potential to transform electric vehicle technology and energy storage solutions. Valued at around USD 1.5 billion in 2023, it’s projected to reach USD 24.5 billion by 2032, with a CAGR of 36.4%. By 2030, the market may surpass USD 960 million, driven by rising EV demand and safety concerns. Industry drivers include the need for higher energy density, improved safety, and faster charging, prompting major automakers to invest heavily. Technological advantages like solid electrolytes offer better thermal stability, safety, and performance. While high costs and manufacturing challenges remain, innovation and strategic partnerships are accelerating development, positioning solid-state batteries as a key player in the future of electric mobility.

Challenges to Widespread Adoption and Future Outlook

Widespread adoption of solid-state batteries faces significant hurdles due to manufacturing complexity and high costs. Producing these batteries requires advanced processes, driving up initial expenses and demanding new infrastructure investments. Scaling up production won’t reach cost parity with lithium-ion batteries until the early to mid-2030s, limiting early availability mainly to luxury and high-performance vehicles. Material stability and brittleness pose technical challenges, affecting durability and safety, especially with issues like lithium dendrites and thermal management. Long-term testing is still underway to confirm lifespan and fast-charging capabilities. Additionally, sourcing rare materials and establishing supply chains complicate scaling efforts. Infrastructure upgrades and regulatory approvals also slow widespread adoption, but ongoing research and technological improvements promise a more accessible future. Renewable energy innovations continue to drive progress in the sector, potentially alleviating some manufacturing and cost challenges over time. Moreover, advancements in material stability are essential to overcoming technical hurdles and ensuring safety and longevity.

Frequently Asked Questions

What Materials Are Used in Solid Electrolyte Production?

You might wonder what materials go into making solid electrolytes. Common choices include sulfide-based materials like lithium sulfide and phosphorus pentasulfide, which offer high conductivity. Oxide ceramics such as LLZO provide stability, while polymers like polyethylene oxide (PEO) are flexible options. Glassy and composite electrolytes combine inorganic particles with polymers, giving you a range of materials that balance conductivity, stability, and manufacturability for advanced battery design.

How Do Solid-State Batteries Perform in Extreme Climates?

You’ll find that solid-state batteries excel in extreme climates, thanks to their broad temperature range. In cold weather, they retain more capacity and power, thanks to reduced ionic resistance and stability. In hot conditions, they resist thermal breakdown and improve safety. Rapid charging, long cycle life, and enhanced durability make them reliable, reducing risks of overheating or failure. Overall, they perform consistently, ensuring your vehicle remains efficient and safe in any environment.

What Are the Recycling Methods for Solid-State Batteries?

Imagine unraveling a tightly woven tapestry—recycling solid-state batteries requires specialized methods. You face challenges like fused components that resist separation and the need for high-quality material recovery. Techniques such as cold sintering, dissolving polymer layers, and innovative models like EverBatt help you recycle efficiently. These methods aim to minimize waste, conserve energy, and recover valuable materials, paving the way for sustainable, large-scale reuse and environmental harmony in tomorrow’s energy landscape.

How Does Cost Compare to Traditional Lithium-Ion Batteries?

Right now, solid-state batteries are considerably more expensive than lithium-ion batteries, costing between $800 and $1200 per kWh compared to $100–$150. While lithium-ion batteries benefit from decades of manufacturing experience and economies of scale, solid-state batteries face higher production costs due to complex materials and processes. However, experts predict that by 2030, solid-state costs could drop to $80–$90 per kWh, making them more competitive.

When Will Solid-State Batteries Be Widely Available Commercially?

You’re wondering when solid-state batteries will be widely available commercially. Predictions suggest mass production could start around 2025, with some companies like Toyota and BYD aiming for large-scale production by 2026 or 2030. However, it may take a few more years for these batteries to become common in vehicles, as manufacturers work through technical challenges and scaling up. Expect gradual adoption to begin in the late 2020s.

Conclusion

While solid-state batteries promise to revolutionize your electric vehicle experience with better range and safety, don’t get too excited just yet. The tech’s potential is undeniable, yet hurdles remain that could keep you waiting longer than expected. It’s ironic how the very innovation meant to accelerate electric mobility might still be held back by challenges, reminding you that even the most promising breakthroughs often face a slow, cautious road to reality.